It’s Time for a Brewer’s Union

It’s time that the brewing industry recognizes the physical and mental strains brewers endure in order to produce a delicious product. Specifically, those not in the brewhouse, cellar, or production floor, need to be aware of the wide range of skills required to brew. A brewer wears many hats. Most people envision a brewery job as: recipe creation, brewing, and drinking beer. There are so many more skills that a brewer needs to have, that they find themselves swamped in a pile of paperwork, sani, unsafe conditions, and unpaid overtime.

Recipe Creation

Every brewer has a different process of recipe creation. And every brewery has a different level of autonomy for that brewer. Some brewers research style guidelines and try to hit the target perfectly, some research the styles to break those rules, others go by the ingredients have they on hand. Some are even told by upper management the style the company wants, or the color, or the hoppiness. It’s unfortunately pretty common to have a brewer who creates recipes, but doesn’t get to be the one designing them. This is the part of the job that most brewers live for. However, a large change in a brew recipe will only change the smallest of tasks in a brewer’s work day.

Laborer

Brewers expect to be on the move constantly. Running from the malt truck to the mill, back to the kettle real quick, back to the cellar to flip a valve, then right back to the brewhaus where you carry up a 5 gallon bucket of hops in each hand. You’re wet, your back will hurt, you’re only half way through your shift, and this whole time you’ve actually been brewing 4 beers all in different stages. A brewer has tons of physical labor that takes its toll all day, every day.

Babysitter

Brewers are at the brewery more than they are home. They work insanely long hours on long shifts because brewing is an organic process. It doesn’t stop and it doesn’t care that you have an appointment to get to. Fermentation can take anywhere from 2 weeks to 6 weeks to completion, and you can bet there are brewers right now waiting for that tank to cap so they can get off the clock.

Mascot

Ok, not only are brewers doing their brewing jobs, but they are also expected to be the face of their brewery. They should stop in the middle of their work and talk to a tour group. To host events after hours in the tasting room. To go to another tap room to promote a new brew. To show up and participate at beer releases. These are generally hours that are crucial to brewery marketing – but are UNPAID. Customers and reporters want to come hang out, meet the brewer, or have a beer dinner. Brewers do this all the time, with gusto, without compensation.

Janitor

The industry joke is that Brewing is actually just cleaning. Cleaning fermentation tanks, conditioning tanks, various brewing vessels, tools, the floor, the walls. Scrubbing every last surface with caustic and with acid. Sometimes its boiling water on a hot day, and sometimes it cold water on a freezing day. Either way, when a brewer does ANYTHING, they first clean, clean, clean – and it doesn’t matter the climate outside.

Handy(wo)man

Breweries break down more frequently than you think. Shit breaks. All the time. Imagine using a piece of equipment or machinery that is always wet, exposed to harsh chemicals daily, and used 24/7. This is a piece of equipment that will be on constant maintenance – or it will constantly break. Brewers need to be able to fix motors, electrical problems, find that one valve that isn’t closing all the way and replace it. Add in finding the extremely rare replacement part, ordering it, and installing it. Welding is a constant job at a production brewery, and those who have this skill are that much more marketable, but not paid much more.

Heavy Machine Operator

Moving different starting materials (malt, hops, etc) is not always done by hand – most are done driving vehicles like forklifts and pallet jacks. Many breweries don’t require any safety training, or prior knowledge to operate said machine. Yet it is expected that a brewer utilize these tools daily.

Statistician

Brew logs, brew logs, brew logs. Brewers measure and record every step they take. From temperatures to running time to volume to quantity to gravities. One brew has the potential to fill an entire page of data. Brewers are expected to not only keep records, but also be able to look back at the logs and find consistency problems, areas for improvement, and where money can be cut back.

Government Liaison

Brewers find themselves in charge of trying to comply with environmental regulations such as storm water and wastewater. Breweries are heavily regulated, and this is seen both statewide and federally. Did you know you can’t dump anything down the drain that has a pH below 5.5? Guess where beer lies for acidity – right around 4.5, which means the brewer has to find a way to treat what is dumped before it reaches the sewer, or face heavy fines, and terrible press for effing up the environment. But this is just one parameter that has to be monitored, there is paperwork to file for 3-4 different annual permits, monitoring that has to be done weekly and sometime even daily. Agencies will constantly show up for a quick inspection, and request all the reporting you’ve been doing on your parameters. Most brewers aren’t even prepared when they get slapped with their first inspection, nonetheless it’s a job their expected to take charge on.

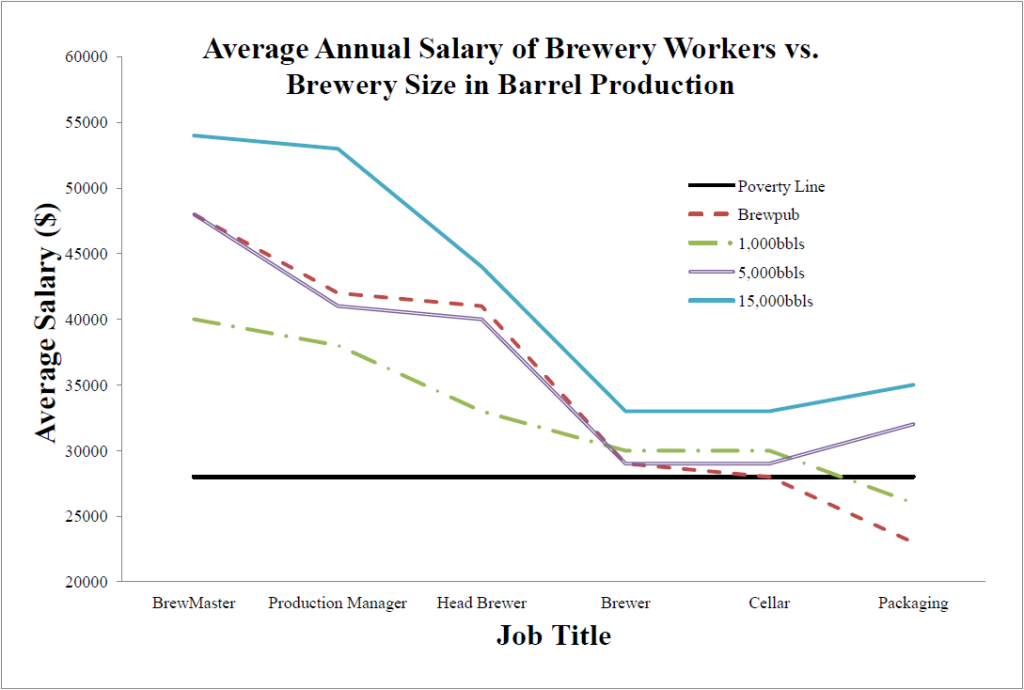

Despite this enormous range of expected skills, brewers are paid shit. Can we finally say this out loud? Brewers are not paid nearly enough for their work. Unless you work for a unionized macrobrewery, brewers make somewhere between $30k and $40k a year (NOTE: this only $2k above the average poverty line for a family of four). If you happen to be a BrewMaster, you’re lucky enough to have that range increase to $40k – $55k a year. And, pointing out, these guys are on a 40 hour a week SALARY. Which means all the extra jobs and hours are not compensated for. These stats are according to the Brewer’s Association yearly report Brewery Operations Benchmarking Data (BOBS) 2014. I threw together the following chart from the data provided to demonstrate the average wages for different production jobs at different brewery sizes.

My purposed solution is this: Unionize.

Union workers, on average, earn higher wages and get more benefits than workers who don’t have a voice on the job with a union.” – International Union of Operating Engineers

It’s time to stand together and fight for the pay, the benefits, and the working conditions you have ALREADY earned. Unions have been an American right since the 1800s in reaction to the industrial revolution. This is the Craft Beer Revolution, and it’s time to get what you deserve. Unions set standards across the industry for your wages, benefits, skill level, training and safety conditions. Under unions you have a voice about your schedule, your hours, your paid, your benefits, your working environment, your continued education, and your right to fair treatment.

Brewers do what they because they love beer. I think it’s time that brewers get paid for all the work that goes into brewing that beer.

I am interested in possibly unionizing our brewery and possibly joining forces with other production craft breweries for many reasons. Obviously strength in numbers helps. Where do we start and can it work?

I think it can work, but it’s going to take a LOT of work. First steps are to find a current union that fits in line with brewers’ goals. Then; getting the word out. I think there needs to be a majority vote within each company. Are you up for the challenge?